I blew it up!

#21

Link away, fellow Saturn owner.

Thank ya kindly.

Please post as its own thread in the general tech section with an appropriate title like accessing the PCV blah blah blah on a (insert year insert model insert trim).

if I gather enough ambition all in one place at one time, I can go over there and hijack the content and put it in your post on our site.

Is it leaking or burning oil?

If it is oozing out anywhere that there is a seal then likely the crankcase pressure is still too high.

Thank ya kindly.

Please post as its own thread in the general tech section with an appropriate title like accessing the PCV blah blah blah on a (insert year insert model insert trim).

if I gather enough ambition all in one place at one time, I can go over there and hijack the content and put it in your post on our site.

Is it leaking or burning oil?

If it is oozing out anywhere that there is a seal then likely the crankcase pressure is still too high.

#22

The oil is leaking from and around the oil pressure switch (which I replaced thinking it was the culprit and it was not). The entire oil pan is wet, but the burning is coming off the exhaust pipe directly under the front (front of engine location) of oil pan. I don't know what more I can do to fix the PCV any better than I did. The DIY reed valve now flaps open rather easily vs my first go. I'm going to test the crankcase pressure during the next run to see if any pressure builds up and is released when I remove the oil cap.

Hopefully, I didn't miss any steps in my description of taking the engine apart to access the PCV. I firmly believe all PCV modules have long past reached their service life. The reed material was hard as and brittle as charcoal. I simply rebuilt the reed valve using a piece of Viton rubber. Just make sure the reed is able to move freely. How the two engine ports beneath the PCV module actually function is unknown to me. They definitely got to separate areas in the motor and how this works to eliminate crankcase pressure is a mystery to me. I looked for engine port diagrams, but didn't find any. It sure would be easier to understand how the PCV module works if I knew where the ports go in the engine.

Hopefully, I didn't miss any steps in my description of taking the engine apart to access the PCV. I firmly believe all PCV modules have long past reached their service life. The reed material was hard as and brittle as charcoal. I simply rebuilt the reed valve using a piece of Viton rubber. Just make sure the reed is able to move freely. How the two engine ports beneath the PCV module actually function is unknown to me. They definitely got to separate areas in the motor and how this works to eliminate crankcase pressure is a mystery to me. I looked for engine port diagrams, but didn't find any. It sure would be easier to understand how the PCV module works if I knew where the ports go in the engine.

#23

Correction, auto correction is changing RTV to ATV, but I think you know what I meant a few post ago.

Saturn is still here even though I was very close to calling the junk yard for pickup after I changed out B2S1 O2 sensor. Prior, the code reader indictated B2S1 so I replaced it. With the new Bosch 16066 Oxygen Sensor installed properly the code reader says all O2 sensors are bad. PO134, PO154, PO300, PO136, and PO156. This is ridiculous! I verified the O2 sensor heater fuse ING-1 was good. So what's going on here?

Bad ground on the ECM or PCM? Could I have disconnected the ground somewhere and failed to reconnect it after I changed the oil pan gaskets? I'm at a lost.

With the new O2 installed it wouldn't hardly run, not even at high rpms. Weather is terrible today, but I disconnected the O2 connector and was able to get the engine to run smoothly at 1100 RPMs but I had to stay on the gas peddle to keep it running smoothly. Any lower RPMs and it started missing, at 600 RPMs it ran badly signaling a potential vacuum leak or possibly a toasted exhaust system. I plan on taking out the new O2 sensor and see if the engine idles normally with it removed to bypass bad exhaust system. I did replace the muffler just before the engine really started to puke oil and burn on the exhaust pipe under the front end of the engine. I can't help to think perhaps the new muffler is plugged and/or the cat has failed. Too many iterations!

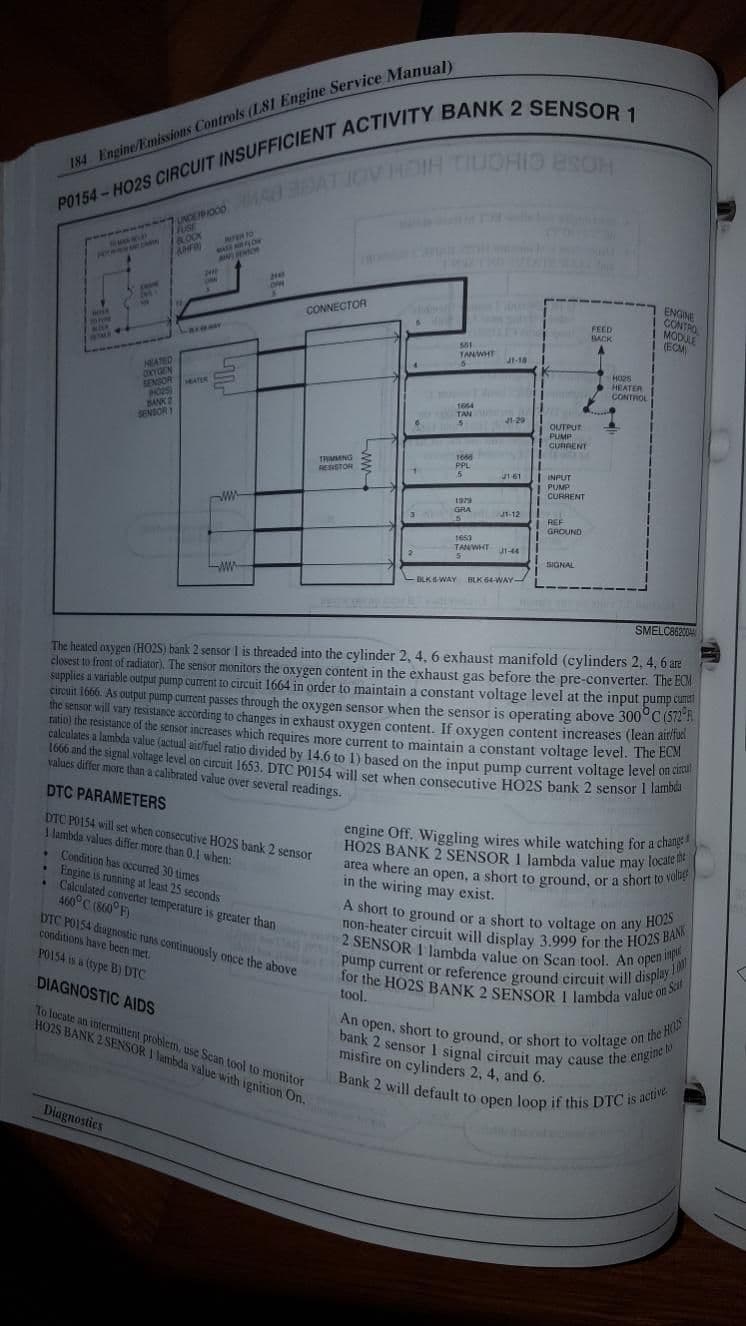

I want to ring out the wiring, but I need engine schematics to do so. I can't follow wires that disappear into wiring "tubes" etc... I need schematics to figure out what is good and what is not.

Saturn is still here even though I was very close to calling the junk yard for pickup after I changed out B2S1 O2 sensor. Prior, the code reader indictated B2S1 so I replaced it. With the new Bosch 16066 Oxygen Sensor installed properly the code reader says all O2 sensors are bad. PO134, PO154, PO300, PO136, and PO156. This is ridiculous! I verified the O2 sensor heater fuse ING-1 was good. So what's going on here?

Bad ground on the ECM or PCM? Could I have disconnected the ground somewhere and failed to reconnect it after I changed the oil pan gaskets? I'm at a lost.

With the new O2 installed it wouldn't hardly run, not even at high rpms. Weather is terrible today, but I disconnected the O2 connector and was able to get the engine to run smoothly at 1100 RPMs but I had to stay on the gas peddle to keep it running smoothly. Any lower RPMs and it started missing, at 600 RPMs it ran badly signaling a potential vacuum leak or possibly a toasted exhaust system. I plan on taking out the new O2 sensor and see if the engine idles normally with it removed to bypass bad exhaust system. I did replace the muffler just before the engine really started to puke oil and burn on the exhaust pipe under the front end of the engine. I can't help to think perhaps the new muffler is plugged and/or the cat has failed. Too many iterations!

I want to ring out the wiring, but I need engine schematics to do so. I can't follow wires that disappear into wiring "tubes" etc... I need schematics to figure out what is good and what is not.

#24

You didn't put any type of teflon or anti-seize on the threads of the O2 sensor did you? Some vehicles use the sensor itself for a ground connection. Most O2 sensors I've ever seen had a little bit of compound on the threads from the factory. I think the aftermarket stuff doesn't conduct. IDK, just trying to go by an old, two brain surgeries memory. It doesn't work that great.

#26

Testing Results Corrected for O2 Sensor heater ohm measurements

B2 S1 in exhaust, but disconnected. This is the way I ran it yesterday and once today before I changed anything

Codes: P0050, P0300 and PO115 I cleared the codes to move on to next step

I removed B2, S1 and found it to be black just like the one I replaced. I also removed B1 S1 and it was white. Then I ran the engine to test for plugged up exhaust. It made no difference, the engine ran poorly at low RPMs with or without O2 sensors installed in exhaust. It was loud and I didn't hear any backfiring, but it was missing badly at low rpms and could hardly remain running. I did step on the gas and it cleaned up a bit. Luckily the apartment mowers were running and I got away with the stock car sounding engine! I liked it! LOL Codes were as to be expected P0030 and P0050

I still have no idea what the 5 wires of each O2 sensor connect to. I did measure between the Wht and Grey thinking perhaps that is heat V+ and V- I got these results

Old B2 S1 O2 Sensor that was replaced 3.5 ohms

New replacement B2 S1 O2 Sensor 3.6 ohms

B1 S1 O2 Sensor was 3.7 ohms

Why such a difference? I hope this isn't another situation like the rear struts where the same part number is actually different versions!

Compression tester has not arrived. So this will be the extent of the testing for today. I'm going to reinstall the original O2 Sensors and perhaps try to return the one I purchased... it just seem right.

Can anyone supply advice on the results?

B2 S1 in exhaust, but disconnected. This is the way I ran it yesterday and once today before I changed anything

Codes: P0050, P0300 and PO115 I cleared the codes to move on to next step

I removed B2, S1 and found it to be black just like the one I replaced. I also removed B1 S1 and it was white. Then I ran the engine to test for plugged up exhaust. It made no difference, the engine ran poorly at low RPMs with or without O2 sensors installed in exhaust. It was loud and I didn't hear any backfiring, but it was missing badly at low rpms and could hardly remain running. I did step on the gas and it cleaned up a bit. Luckily the apartment mowers were running and I got away with the stock car sounding engine! I liked it! LOL Codes were as to be expected P0030 and P0050

I still have no idea what the 5 wires of each O2 sensor connect to. I did measure between the Wht and Grey thinking perhaps that is heat V+ and V- I got these results

Old B2 S1 O2 Sensor that was replaced 3.5 ohms

New replacement B2 S1 O2 Sensor 3.6 ohms

B1 S1 O2 Sensor was 3.7 ohms

Why such a difference? I hope this isn't another situation like the rear struts where the same part number is actually different versions!

Compression tester has not arrived. So this will be the extent of the testing for today. I'm going to reinstall the original O2 Sensors and perhaps try to return the one I purchased... it just seem right.

Can anyone supply advice on the results?

Last edited by RjAquaponics; 04-30-2020 at 01:48 PM.

#28

Pin 4 and Pin 5 are indeed the heater, but the colors they are showing are not right in this page of the manual. I am likely wrong, but heater 02 Pin 4 is wht and so is the car connector Wht and the heater 02 Pin 5 is grey and the car side is violet. According to the manual Pin 4 is Tan/Wht and Pin 5 is Orange. This adds to the confusion. I have verified pin 4 and pin 5 are the heater windings in the 02 sensor(s).

#29

#30

Pin 4 and Pin 5 are indeed the heater, but the colors they are showing are not right in this page of the manual. I am likely wrong, but heater 02 Pin 4 is wht and so is the car connector Wht and the heater 02 Pin 5 is grey and the car side is violet. According to the manual Pin 4 is Tan/Wht and Pin 5 is Orange. This adds to the confusion. I have verified pin 4 and pin 5 are the heater windings in the 02 sensor(s).

DTC P0030 will set if HO2S bank 1 sensor 1 (firewall side) heater feedback voltage is between 1.60 and 3.60 volts (ECM pull-up voltage) indicating an open circuit when heater is commanded Off. Heater element resistance: 2.4-9.2 ohms

DTC P0050 will set if HO2S bank 2 sensor 1 heater feedback voltage is between 1.60 and 3.60 volts (ECM pull-up voltage) indicating an open circuit when heater is commanded Off. Heater element resistance: 2.4-9.2 ohms.

The ECM controls the heater by pulsing [heater] circuit 751 to ground. When the heater is commanded Off (circuit not grounded), the voltage level at the ECM should be high (ignition voltage). When the heater is commanded On (circuit grounded), the voltage level at the ECM should be low. The ECM heater feedback circuit uses a pull-up voltage (1.6-3.6 volts), which allows the ECM to individually differentiate between an open, short to ground or short to voltage. DTC P0030 will set if the ECM detects an open heater control circuit when the engine is running.